Airless pump bottles are a major innovation in cosmetic and skincare packaging, and in recent years, more and more skincare brands have chosen vacuum pump bottles for their product packaging. Unlike traditional pumps that use straws or tubes to dispense products, airless pump bottles utilize a vacuum mechanism to extract the contents. This design minimizes air exposure, ensuring the product remains fresh and contamination-free. Widely used in creams, lotions, serums, and other high-viscosity formulas, airless pump bottles are favored for their ability to maintain the integrity and efficacy of cosmetics.

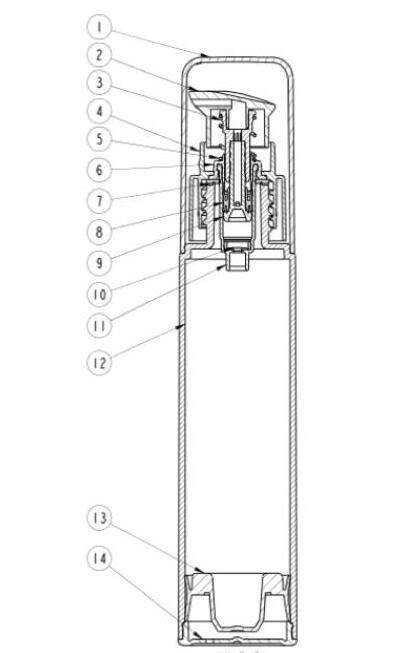

Components of an airless pump bottle

Piston airless pump bottles are the most common type of airless pump bottle. This type of airless bottle has a piston installed inside the bottle, and between the press head to produce a closed space, the contents are stored in this space, by pressing the airless pump press head, prompting the space to make an airless state, and the use of external atmospheric pressure to promote the movement of the piston, to distribute the contents of the airless pump through the liquid outlet hole.

The key point of this technology lies in the piston and the wall of the bottle: the piston and the wall of the bottle can not be too tight or too loose, too tight easy to appear the piston can not be moved so that the liquid can not be pumped, too loose is prone to leakage phenomenon. Therefore, it is limited by the changes in the shape of the package, common round or oval, and other very regular packaging forms.

| No. | Part Name | Material |

|

1 |

Outer cover | PP |

| 2 | Head cap | PP |

| 3 | Valve stem | PP |

| 4 | Large ring | PP |

| 5 | Spring | 2DI |

| 6 | Bayonet seat | PP |

| 7 | Gasket | PE |

| 8 | Small piston | LDPE |

| 9 | Valve needle | POM |

| 10 | Spring sleeve | LDPE |

| 11 | Pump body | PP |

| 12 | Inner bottle | PP |

| 13 | Large piston | LDPE |

| 14 | Base | PP |

Airless Pump Bottles vs. Traditional Pump Bottles

| Feature | Airless Pump Bottles | Traditional Pump Bottles |

| Mechanism | Utilizes a vacuum system with a piston or diaphragm to dispense product. | Uses a straw or tube to draw product up through the pump mechanism. |

| Air Exposure | Minimal to no air exposure, preserving product integrity. | Air enters the bottle with each use, leading to potential oxidation and contamination. |

| Product Preservation | Extends product shelf life by protecting from air and contaminants. | Shorter shelf life due to exposure to air and potential contaminants. |

| Product Usage | Allows nearly all of the product to be used, reducing waste. | Often leaves significant product at the bottom, leading to waste. |

| Contamination Risk | Low risk due to airtight design. | Higher risk due to repeated air exposure and potential backflow. |

| Suitable Formulations | Ideal for high-viscosity and sensitive products, such as serums and creams. | Suitable for less viscous products but may struggle with thicker formulations. |

| Ease of Use | Consistent and precise dispensing; no need to keep the bottle upright. | May require shaking or tilting to get the last of the product. |

| Eco-Friendliness | Often refillable and reusable, reducing packaging waste. | Typically single-use, contributing to more waste. |

| Design Flexibility | Can be designed with various materials and shapes to suit different products. | Limited design flexibility due to the need for a tube or straw. |

| Consumer Perception | Seen as more premium and high-end due to advanced technology and benefits. | Viewed as standard and less innovative compared to airless options. |

Advantages of Airless Pump Bottles

1. Maintain product quality and efficacy: The vacuum pump bottle can keep the product in a vacuum state, preventing the product from direct contact with the air, and maintaining the integrity and effectiveness of the formula.

2. Reduce the risk of contamination: The airless seal can prevent bacteria in the air from entering the bottle and prevent bacterial growth.

3. Minimize waste and precise distribution: The vacuum design allows users to enjoy every drop of the product.

Through the above content, we understand the working principle of vacuum pump bottles, the differences and advantages of traditional pump bottles, etc. Vacuum pump bottles can protect the integrity, freshness, and safety of your skincare formula. Especially for some sensitive products, in order to maintain the efficacy and service life of the product, vacuum pump bottles are the best choice. Sincerely recommend you to use our latest airless pump bottle series to take your skin care products to a new level.